Torlon® PAI (polyamide-imide) combines the exceptional performance of thermoset polyimides with the melt-processing advantage of thermoplastics. Wear-resistance grades offer unsurpassed performance in both dry and lubricated environments. High-strength grades retain their toughness, high strength and high stiffness up to 275 °C (525 °F), making PAI the industry’s highest performing thermoplastic. Its broad chemical resistance includes strong acids and most organics.

Polytetrafluoroethylene is better known by the trade name polymer®. It’s used to make non-stick cooking pans, and anything else that needs to be slippery or non-stick. PTFE is also used to treat carpets and fabrics to make them stain resistant. What’s more, it’s also very useful in medical applications. Because human bodies rarely reject it, it can be used for making artificial body parts.Polytetrafluoroethylene, or PTFE, is made of a carbon backbone chain, and each carbon has two fluorine atoms attached to it. It’s usually drawn like the picture at the top of the page, but it may be easier to think of it as it’s drawn in the picture below, with the chain of carbon atoms being thousands of atoms long.

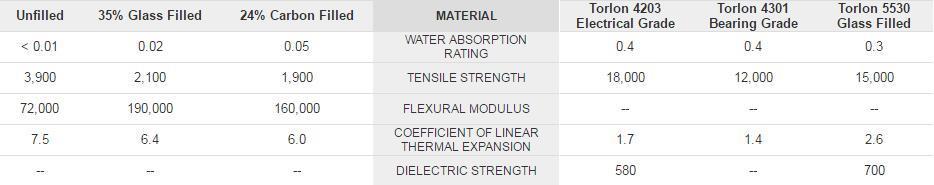

Comparison of polymer PTFE/FEP and Torlon Property Values

Material Applications

polymer PTFE/FEP:Cabling solutions;Non lubricated bearings;O-rings;Seals;Capacitors;Semiconductor manufacturing;High temperature electrical parts;Gaskets;Valve components.

Torlon:Aerospace;Pump components;Valve seals;Bearings;Rollers High Temperature Insulators;Parts for electronic equipment manufacture;Replacement of metals and ceramics.

Material Properties

polymer PTFE/FEP:Excellent dielectric properties;Inertness to most chemicals;High heat and chemical resistance;Very low coeffiecient of friction;Excellent radiation resistance;Zero moisture absorption;Relatively insensitive to power frequency;Machinability.

Torlon:High dimensional stability;Low creep;High thermal endurance;Machinability.

Post time: Jul-14-2018